Software

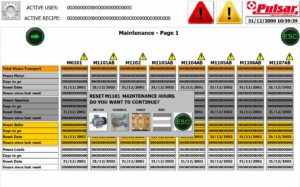

To address the needs of the Tissue industry, Pulsar Engineering has developed advanced line management tools. Drawing from extensive experience in installing conveyor systems, Pulsar Engineering designs hardware and software solutions that manage and optimize entire production lines, such as the REDS family of Software Supervising Systems and the predictive maintenance software PWS.

Pulsar Engineering’s patented predictive maintenance software, the Harmonizer, along with the REDS platform, collects operational data to measure line efficiency, monitor the production line, identify critical issues, and suggest improvements.

The software integrates individual machines into a cohesive system where they communicate and interact to enhance overall system performance and increase production capacity. Additionally, Pulsar Engineering’s intelligent control systems help customers reduce energy consumption, improve efficiency, maintain consistent production quality, and minimize production waste through a predictive maintenance approach.