software

To meet the ever-growing needs of the Tissue industry, Pulsar Engineering has created sophisticated line management tools,

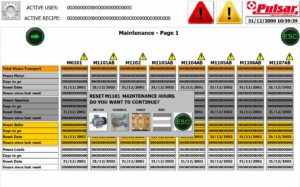

With the experience gained from installing hundreds of conveyor systems, Pulsar Engineering can create hardware and software combinations to manage and optimize entire lines, such as the REDS family of Software Supervising Systems or the predictive maintenance software PWS.

Pulsar Engineering’s patented predictive maintenance software, the Harmonizer and the REDS platform, enable the measurement of line efficiency by collecting operational data and monitoring the entire production line, identifying any critical issues and possible improvements.

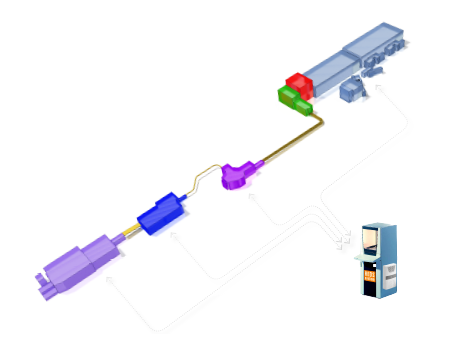

Thanks to Pulsar Engineering’s software, the line will no longer be a mere system of machines, but an integrated system in which individual machines dialogue and interact with each other in order to optimize the entire system and increase the production capacity of the entire line.

With intelligent control systems, Pulsar Engineering can support customers to reduce energy waste, achieve increased efficiency, smooth production quality and reduced production waste, a predictive maintenance system.