REDS System Harmonizer

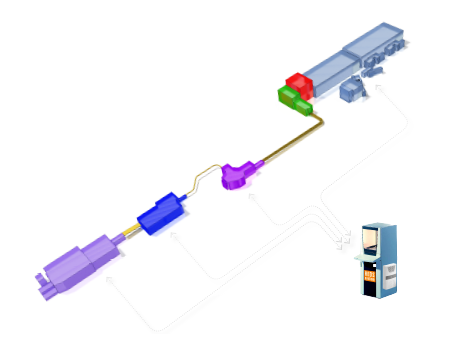

Often within a line, machines are simply connected to each other, without an overall view, thus limiting the overall production and functional potential of the entire converting line.

Pulsar Engineering’s intuition was to create patented software able to transform the line into an integrated system in which individual machines can communicate and interact with each other, optimizing investments and properly using the space available within the industrial plant.

With the harmonizer, it is possible to calculate in real time the speed value to be assigned to the machines in the line and adjust them automatically according to the events occurring in the plant, preventing the stoppage of one of the machines from causing the entire line to stop.

Within the system there are photocell barriers that monitor the line fill level and allow the harmonizer to make positive or negative corrections to the speed reference calculated for the machines.

Thanks to the Pulsar Harmonizer, it is possible:

- Make the machines in the converting line part of a single process;

- Create a constant product flow, from the beginning to the end of the paper converting process, allowing constant operation of the machines, without continuous stops and restarts;

- Benefit from a single point of control and data visualization: integration between the various PLCs of the processing and packaging machines through customized software;

- Avoid the task of machine adjustment for operators, enabling more effective quality control;

- Save production data and maintain full traceability;

- Plan production according to different types of products;

- Reduce routine and extraordinary line maintenance;

- Maximize the production capacity of the entire line.