Pulsar Warning System - PWS

Focusing on the efficiency of systems and the optimization of production processes also means being able to plan maintenance activities exactly when it is necessary. Incorrect maintenance planning leads to incurring unplanned breakdowns that can result in extensive damage or downtime, but also to high costs for unnecessary maintenance work.

To support Customers in improving efficiency and process optimization, Pulsar Engineering has introduced tools for the management of control operations and preventive maintenance in the systems of its plants, able of suggesting proper planning of maintenance interventions according to precise parameters.

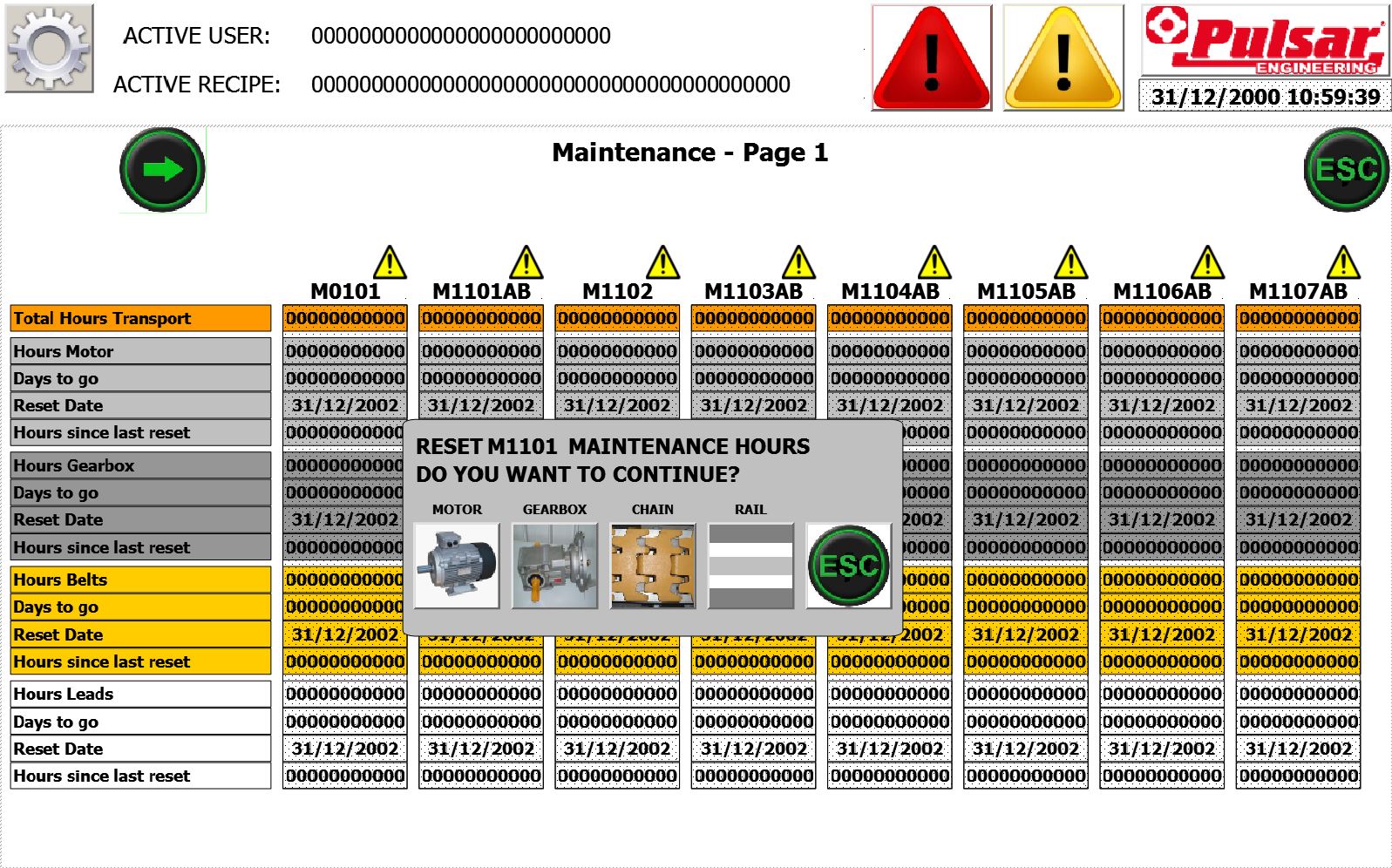

The Pulsar Warning System (PWS) software can monitor the total hours of operation of motors, gearboxes, chains and any other component on the line, as well as check the level of energy consumed in a specific time interval, information that is used to adapt the maintenance and control plan.

The PWS allows two levels of time alert, preset to specific values for each component to be monitored: when the first level is exceeded, the operator will receive an alert on the panel to carry out routine control operations on the component; when the second level of time is exceeded, an alert will be displayed for component replacement.

The advantages of the Pulsar Warning System

Thanks to the Pulsar Warning System the operator will be able to:

- detect in real time the state of wear and tear of the plant's mechanical components;

- reduce downtime by acting preemptively with the necessary checks to avoid deterioration of systems and detect abnormal wear and tear before failure occurs;

- avoid unnecessary costs for undue maintenance and achieving significant savings in maintenance costs, spare parts, and storage of materials in the warehouse;

- reduce environmental impact, through less waste due to prematurely replaced components and through reduced energy consumption due to underperforming components.