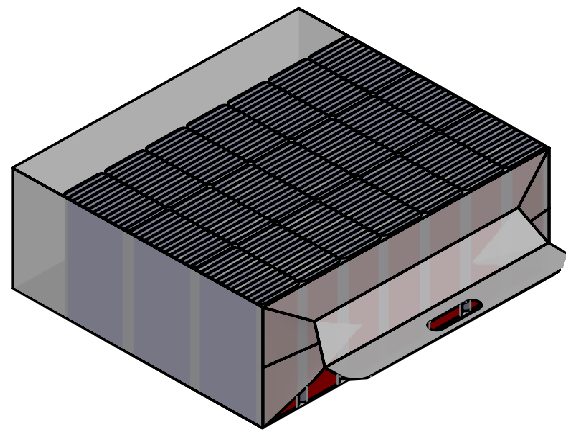

Special Conveyor Units

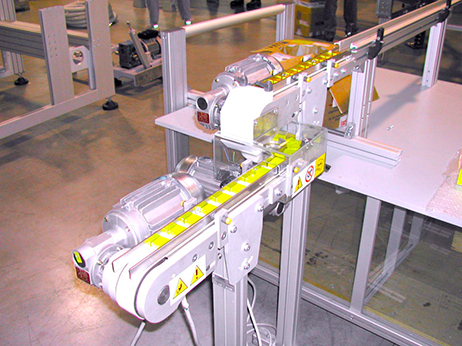

In addition to producing conveyors using standard material, Pulsar Engineering has designed and can develop special conveyors and systems that meet customer requirements. Various types of special conveyors have been created for handling and transporting a wide range of products across all industries. These include:

- special conveyors to be integrated onto an existing line (or with other suppliers), controlled by the electric cabinet of the line;

- special conveyors with their own electric cabinet and are consequently independent from the rest of the system.

These conveyors or units can typically be motorized, but can also be made non-motorized or gravity-fed.

Furthermore, Pulsar Engineering is capable of designing an entire system with special conveyors and providing it to the customer as a “turnkey” solution.

Naturally, special conveyors have been designed in compliance with the requirements of the food and pharmaceutical industries*, and are made using stainless steel or FDA-compliant plastic materials.

*Except for conveyors intended to be placed inside sterile rooms; in such cases, transport specifications must be clarified.

Questi percorsi o gruppi possono essere motorizzati nella maggior parte dei casi ma anche folli e a gravità.

Pulsar Engineering inoltre è in grado di studiare un intero impianto con percorsi speciali e fornirlo al cliente “chiavi in mano”.

Naturalmente sono stati realizzati percorsi speciali conformi alle richieste dell’industria alimentare e farmaceutica*, quindi realizzati con materiale inox o plastico aderente alle norme FDA.

* Tranne percorsi da collocare all’interno di camere sterili; in questo caso è necessario chiarire le specifiche del trasporto.