Quatis Vision – Advanced Product Inspection

Compact, Versatile, and Modular

Vision is a high-precision inspection system using image analysis to check product quality, whether wrapped or unwrapped. It also detects and reads alphanumeric codes via OCR. Its modular design ensures easy integration into new or existing production lines, allowing full customization to meet specific requirements.

Flexible & Scalable Design

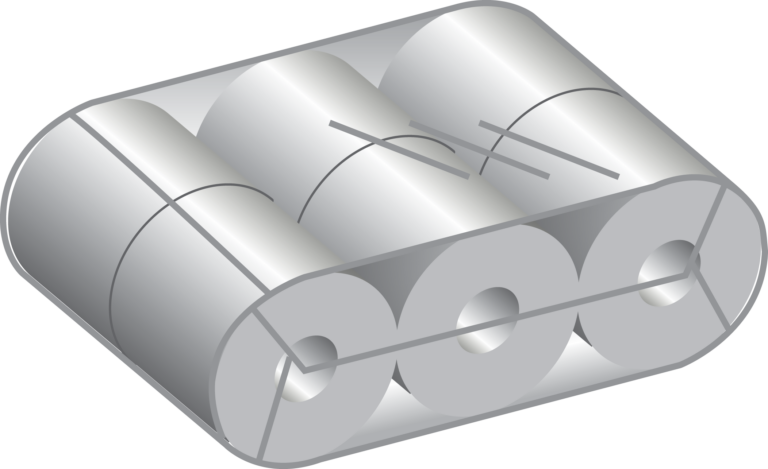

With modular architecture, Vision supports 1 to 6 inspections and consists of six key units:

- Inspection Module – Vision system with electrical cabinets, installable on existing conveyors.

- Ejection Module – Removes non-compliant products.

- Base & Conveyors – Transforms Vision into a standalone unit.

- Conveyor Link Modules (no.3) – Manage speed, 90° rotation, and overturning for optimal inspection.

Smart Connectivity & IoT Integration

Equipped with Ethernet & Wi-Fi, Vision connects seamlessly to company networks for remote monitoring and assistance. A dedicated router enables real-time system diagnostics and automated fault resolution via the Pulsar Remote Assistance Centre.

Data-Driven Quality Control

Vision collects real-time inspection data for process optimization, with:

- Historical Data Analysis – Identifies trends and prevents defects.

- Seamless Data Sharing – Syncs with company networks or external platforms.

- Automated Cloud Reports – Pulsar’s cloud service delivers production reports without manual intervention.

Fully compatible with DB Quatis, Vision ensures advanced reporting and seamless integration into quality control processes.

Detected non-compliances:

- Non-compliant print centering (detection on partial surface);

- Ghost printing detection;

- Text detection and elaboration through OCR;

- Non-compliant side sealing;

- Non-compliant bottom cross sealing;

- Open flaps;

- Non-compliant shape;

- Perforation line detection;

- Non-compliant logos/images (detection on entire surface);

- Paper wrinkles;

- Dirt on the surface.

Some Technical Specifications – QVS / QVS-H /QV-H Quatis Vision machine

Products

Lane

Automatic ejection unit

Max inspection capacity

Compliance checks

Maximum pack dimensions

Weight

Ejection System

Interfolded

1

*up to 120 products minute / QV-H No

up to 120 products minute

up to 6

W 120 – L 250 – H 120

150 Kg

Air blast reject unit / QV-H No

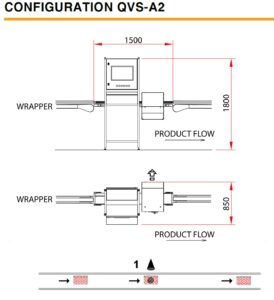

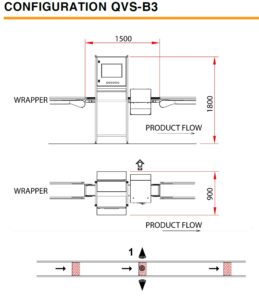

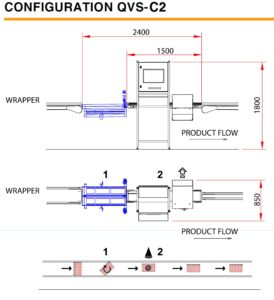

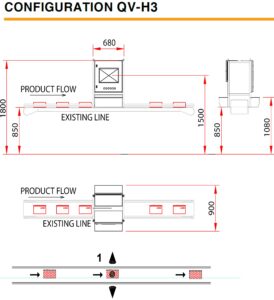

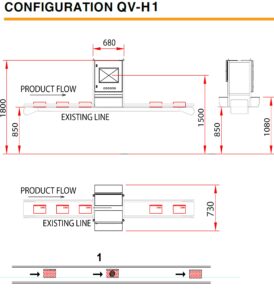

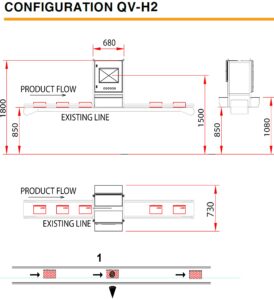

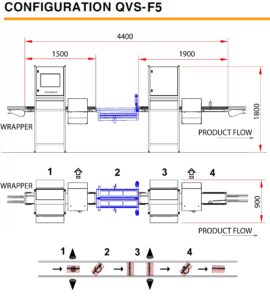

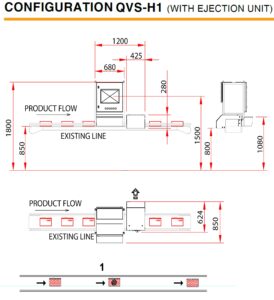

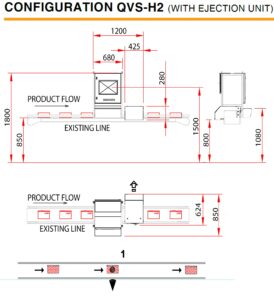

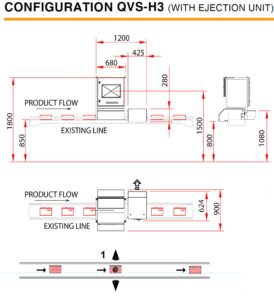

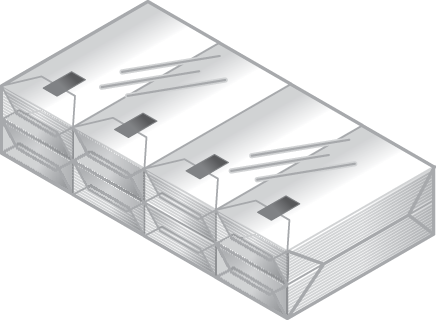

Configurations examples