Bagfiller MBF15

Bagfiller MBF15 folded products The MBF15 Bagfiller is engineered as a modular system able of collate wrapped packs of interfolded paper sheets into pre-selected format, inserting it inside a bag (in plastic or paper), sealing the end and removing the reim. Its single modules ensure that the machine can be configured based on the specific […]

Polaris

Polaris The Polaris bagfiller machine is a modular system engineered to collate AFH rolls into preselected format packs, insert into bags, seal open end of the bags and remove the trim. One of the main features of Polaris is the dual bag feeding principle in one: Single bag produced “just in time” by a bag […]

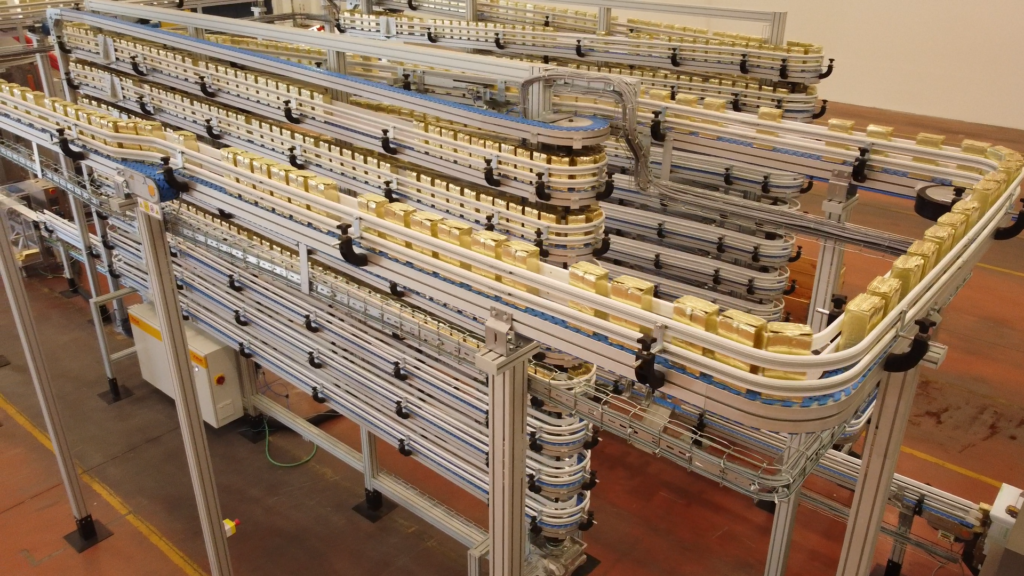

Alpine accumulation conveyors

Alpine accumulation conveyor To meet the need for product accumulation between the upstream and downstream machines, Pulsar Engineering has designed and manufactured various alpine conveyors. The presence of an accumulation buffer in the line helps reduce stoppages of the upstream machine in the event of a downstream machine stop (e.g., for quick maintenance, reel change, […]

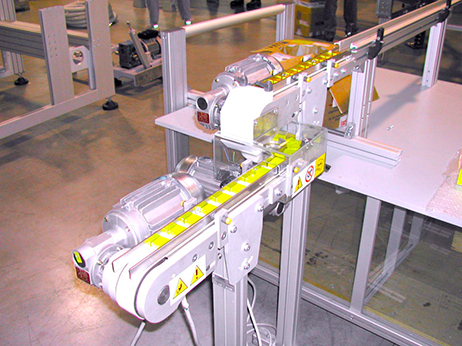

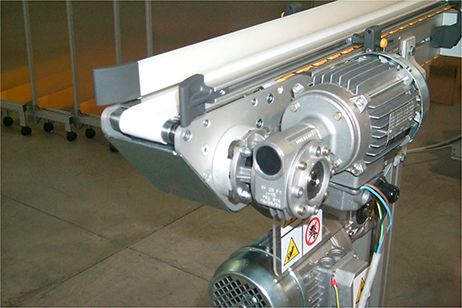

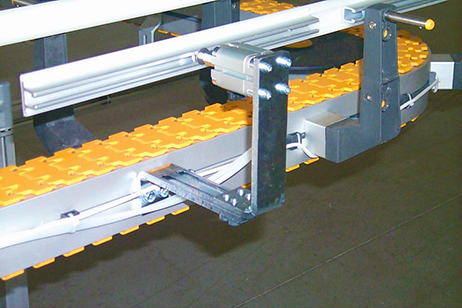

Special Conveyors

Special Conveyor Units In addition to producing conveyors using standard material, Pulsar Engineering has designed and can develop special conveyors and systems that meet customer requirements. Various types of special conveyors have been created for handling and transporting a wide range of products across all industries. These include: special conveyors to be integrated onto an […]

Transfer Units

Transfer Units Most of Pulsar Engineering’s applications need to interface with machines (upstream or downstream) without damaging, disassembling, or moving the product from its preset position. Transfer units have been specifically designed for this purpose. An additional condition arises when products, in certain situations, need to feed downstream machines and be transferred while maintaining their […]

Stop Units

Stop Units The stop units (also known as brake units) are devices that allow for stopping the movement of the product on the conveyor. This function is useful when there is a need, for example, to divert two or more product lines to a single outlet. In this case, the brake unit performs an action […]

Packs Reject Control

Packs Reject Control A device used to discard products coming from the upstream line. The unit is installed along the line and consists of a gravity roller conveyor with a pivot point upstream. The product normally moves along the roller conveyor, pushed by the accumulation of products upstream. When discarding production is necessary, a pneumatic […]

Bridge Ways

Bridge Ways The bridge way is a manually activated unit that allows the operator to cross the line. It is a section of the transport line with a variable length hinged at one end so that it can be overturned in loco to allow passage. The bridge way can be found along any type of […]

Realignment Units for packaged rolls

Realignment Units for packaged rolls To optimize the advancement of packaged rolls, typically single or double toilet roll packages and single kitchen roll package from the exit of the wrapper to the downstream machine, it may be necessary to provide proper reorientation of the pack. Pulsar Engineering has patented the Realignment Unit for Packaged Rolls, […]

Diverter – Sorting Units

Diverter – Sorting units The diverter units are handling units used in processing or packaging lines, that allow for changing the direction of the product being conveyed. They are employed when there is a need to divert the product flow from one line to multiple lines, either vertically or horizontally, facilitating connections between machines with […]