Motorized Elevators and Lowerators

The lifting and lowering units are used to modify the production flow height, with a height difference that does not usually exceed 4 meters (being able to reach 6 meters).

The purpose is to move products vertically and optimize floor space by bridging a gap and creating a passageway allowing operator access.

With due distinctions, elevators and lowerators can be adapted to the handling of rolls, packs or bundles, following the production speed of the upstream and downstream machines in which they are inserted. The only limitations are due to the geometry of the product that need to be transported.

Based on specific needs and based on the products to be conveyed, elevators and lowerators can be made in “C” shape or “S” shape.

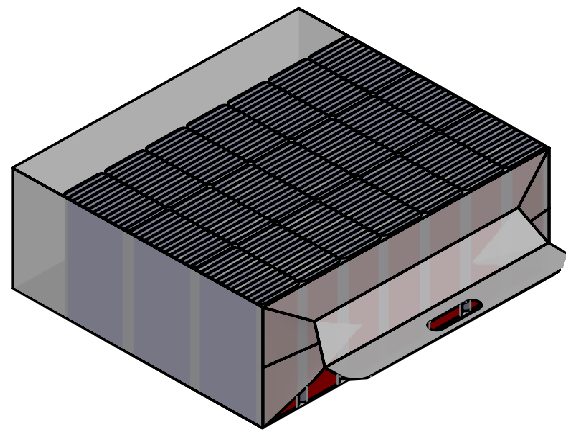

It can be made different types of product advancement system such as:

- Elevators and lowerators with upper chain contrast conveyor;

- Elevators and lowerators with special high grip belt;

- Elevators and lowerators with side chains with flexible inserts.

The motorized elevators and lowerators units made by Pulsar offer numerous advantages, including:

- Space optimization in the layout;

- Easy access for operators;

- Simplified format adjustment from a single point, from one to five ways;

- Elimination of bottlenecks