Diverter - Sorting units

The diverter units are handling units used in processing or packaging lines, that allow for changing the direction of the product being conveyed. They are employed when there is a need to divert the product flow from one line to multiple lines, either vertically or horizontally, facilitating connections between machines with a different number of infeeds and outfeeds.

Thanks to the various configuration possibilities, they can meet different needs.

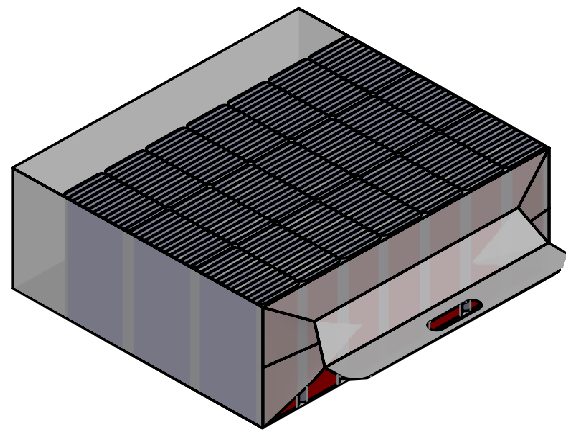

For vertical diversion of rolls, Pulsar Engineering has designed a manual two-position roll diverter. This manually operated unit allows for diverting the flow of rolls coming from one line to one of the two overlapping exit paths. In this case, the shift from one position to another (up-down) is enabled by a hydraulic drive.

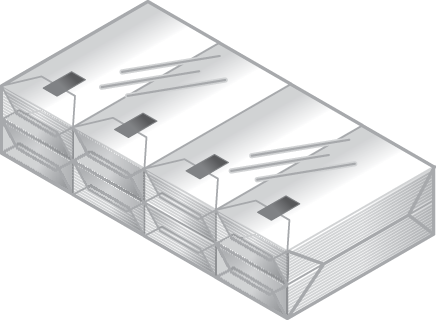

The sorting unit is an automatic device capable of sorting incoming products from one or two horizontal lines. The product is stopped on a fixed stop, detected by a piece presence photocell, and then divided into two lines by an electro-pneumatic actuator. This unit can be set to bypass mode.