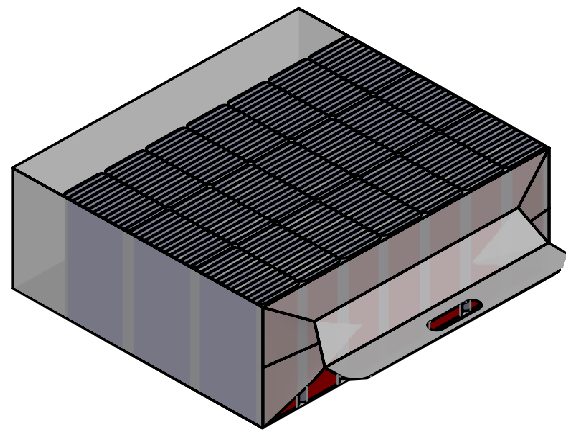

Cores Transfer Units

The system has been designed and patented to convey cardboard cores from the tube-forming machine to the core accumulator.

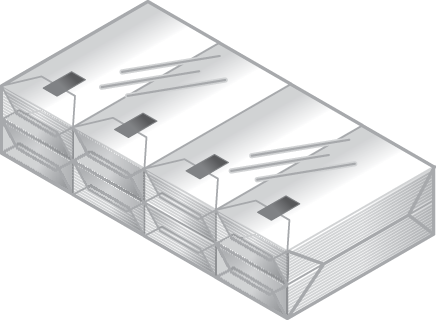

Thanks to the handling unit, the core is transported crosswise to the feed direction, pulled by two chain conveyors composed by simple links or cleated links: the cores are loaded aligned to the exit of the tube-forming machine, unloading them aligned to the core accumulator (or on a Pulsar chain elevator that conveys the products upwards, ensuring space optimization).

This feature prevents the cores, even at high speed, overlapping inside the bend that they form, giving the upstream tube-forming machine greater production speed.

Thanks to the core transfer unit, it is possible to benefit from:

- Optimization of floor space due to more compact layouts;

- Capacity of up to 65 cores per minute;

- No bottlenecks;

- No possibility of cores overlapping on the inside of the bend;

- Increased production speed of forming machines.

Functions:

Core transferring