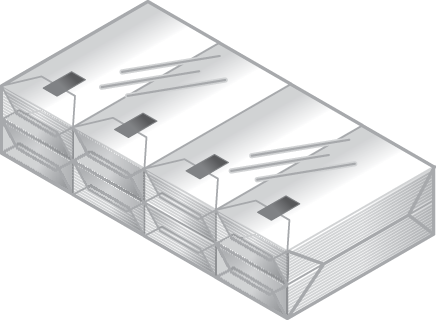

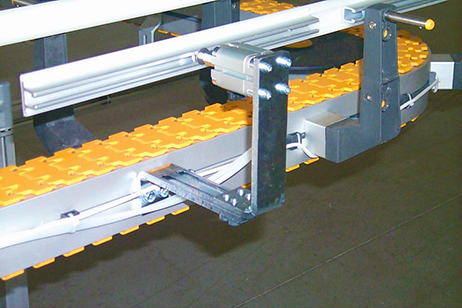

Stop Units

The stop units (also known as brake units) are devices that allow for stopping the movement of the product on the conveyor. This function is useful when there is a need, for example, to divert two or more product lines to a single outlet. In this case, the brake unit performs an action similar to that of a typical traffic light.

Stop units are typically of two types:

- Manual;

- Automatic.

In the case of manual units, the operator decides when to stop a product line by manually moving a barrier or guide.

In the case of automatic units, typically pneumatic, a photocell or timer triggers a solenoid valve connected to the cylinder that acts on the brake. Similar to the manual version, the component that moves is usually a guide or barrier.

Stop units can be customized based on the customer’s needs and the size of the products to be stopped. They do not require special layout considerations, as they do not need space upstream or downstream. The only consideration is the accumulation that may occur during the system’s action.

It is important to carefully evaluate the product’s characteristics (shape, size, contact surface with the transport system, consistency, speed, etc.), to determine if accumulation on chains and/or belts is compatible. In this case, the selection of the appropriate belt characteristics must be considered.

During the design phase, these factors should be taken into account to properly size guides, barriers, cylinders, and solenoid valves.

Sometimes, stop units may be installed in conjunction with other units that require the product to be held in a specific position for processing.