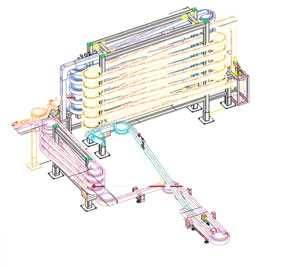

Bulb spiral shaped conveyor system

Shown here is Pulsar’s complete conveyor line system for transporting pallets in the mechanic/electronic industries. The line is made up of spiral-shaped conveyors called accumulators type FI-FO (First In/First Out) and loading and unloading conveyors serving them.

The accumulators are for cooling the just formed bulbs within the pallets by making them travel for 5 minutes between the exit of the forming machine and the entrance of the wrapping machine.

Their other function is to prevent the forming machine from going into continuous start/stop after the machines’ downstream halt. This is because the upstream halts are far more wasteful and longer to manage.

The accumulator made up for the downstream halts by continuing to incorporate the outgoing pallets until it reached maximum saturation.

It is important to note that motorization in spiral shaped accumulators comes about in the curves so that chain pulling is reduced enough to move one spiral at a time.